In amongst our many road car projects and a packed summer schedule on track, we’ve also been busy preparing for the 2017 East African Safari Classic Rally. Our cars are just about ready for a big test back down in Wales this week, before they ship to Mombasa in early September.

Preparations on all of our Safari cars have involved a full bodyshell strip, down to the basics. The shells have been checked for damage and any repairs carried out by the fabrication team before the cars are sent to the body shop and freshened up with a new coat of paint. Sounds like a nice, easy project when you say it fast enough, but of course it takes weeks to re-prepare a car that has been rallied flat-out across the African wilderness for thousands of kilometres! Some of these cars completed a private event towards the end of last year, so the body refurb has been less intensive, but preparation still adds up to a long list of jobs.

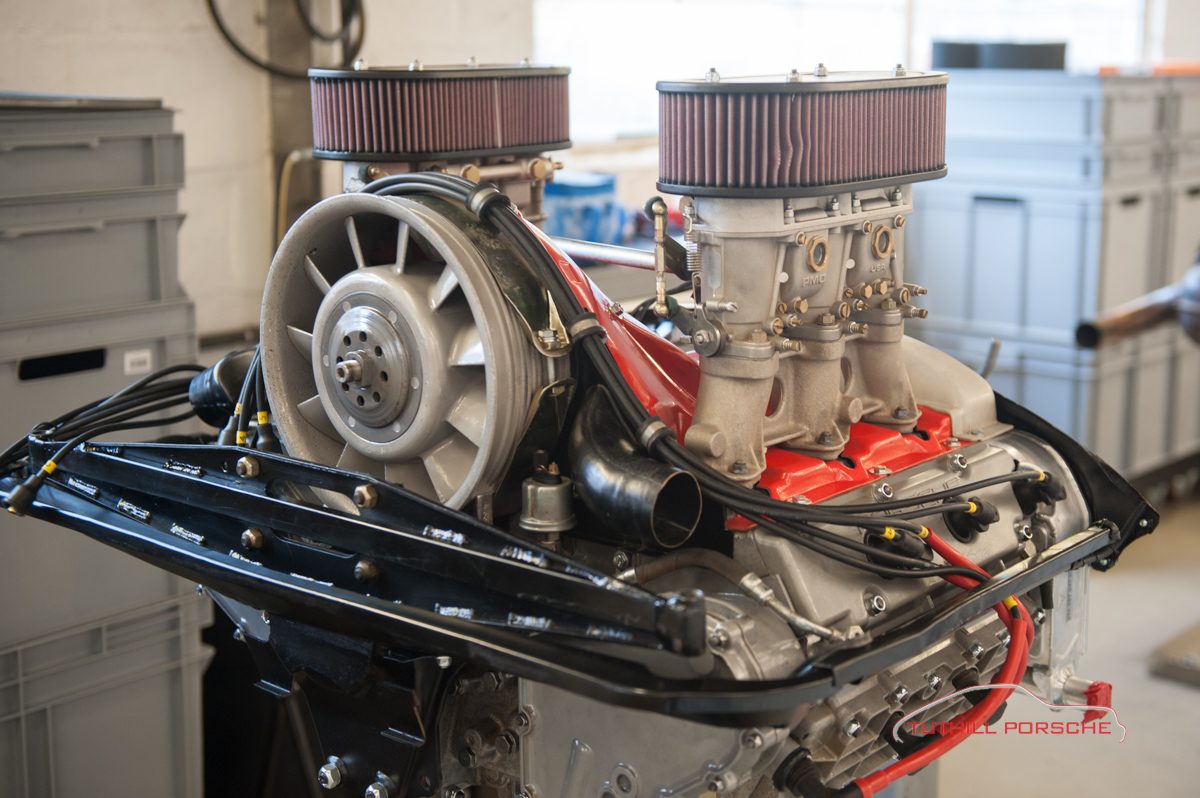

While the bodyshell refurb is in progress, the major mechanical components on each car are stripped and overhauled. Dampers are replaced with rebuilt items and the old ones are sent away to be fully reconditioned. Many other suspension parts and brake discs, pads and calipers are replaced, while we also rebuild steering racks, go through the electrics and make sure race seats and belts are in date and undamaged.

Alongside the car rebuilds, there is a huge logistics challenge to work through. The personnel list is set early on and we have to confirm all of our team is available. Then we sort travel arrangements: flights, hotels, vehicles and transfers. There are visas and inoculations to organise. We also have physios and a medic team to organise and equip. A long list of spare parts must be ordered and stock of these items is not always guaranteed, so our parts department is always working under pressure to gather all the spares we need to take with us.

Spare engines and transmissions are prepared, along with checking wheels and tyres and ordering any special tyres that may apply. The entire operation is a huge undertaking that stretches our team to the limit, so there’s a great sense of relief when container loaded up with cars and parts finally leave Wardington.

The shakedown in Wales is designed to highlight issues that may need attention at the workshop before we send the cars to Africa. While we do bring a comprehensive travelling repair shop with us, it is a lot easier to carry out some repair jobs in England before the cars arrive on another continent, where they will be staying until early December.

The upcoming test should be an exciting day, so we’re bringing a video crew with us. We’re putting four of our Safari 911s through their paces, so the footage is bound to be mega! We’ll share that with you as soon as possible.

Back to News

Back to News