The Tuthill Porsche workshop is about to close for its traditional end-of-year shutdown, but there has been no let up in pace for the team busily preparing our Below Zero Porsche Ice Driving cars for the 2017 season.

Below Zero is held on the frozen lakes around Åre in Sweden during the first three months of every year. We’ve been running our ice driving seasons for over a decade so we know only too well what the cars will have to endure in this hostile environment! Preparing them is not a small job.

Refreshing a Below Zero Ice Driving car following a typical season starts with removal of the engine and transmission. The bodyshell then goes into our fabrication shop, where any dented panels or damaged bodywork is repaired. Most seasons give us new cars to prepare, which involves adding seat mounts, roll cages and other special parts. The new 914 we have joining us this season is a good case in point, but that’s a subject for another day!

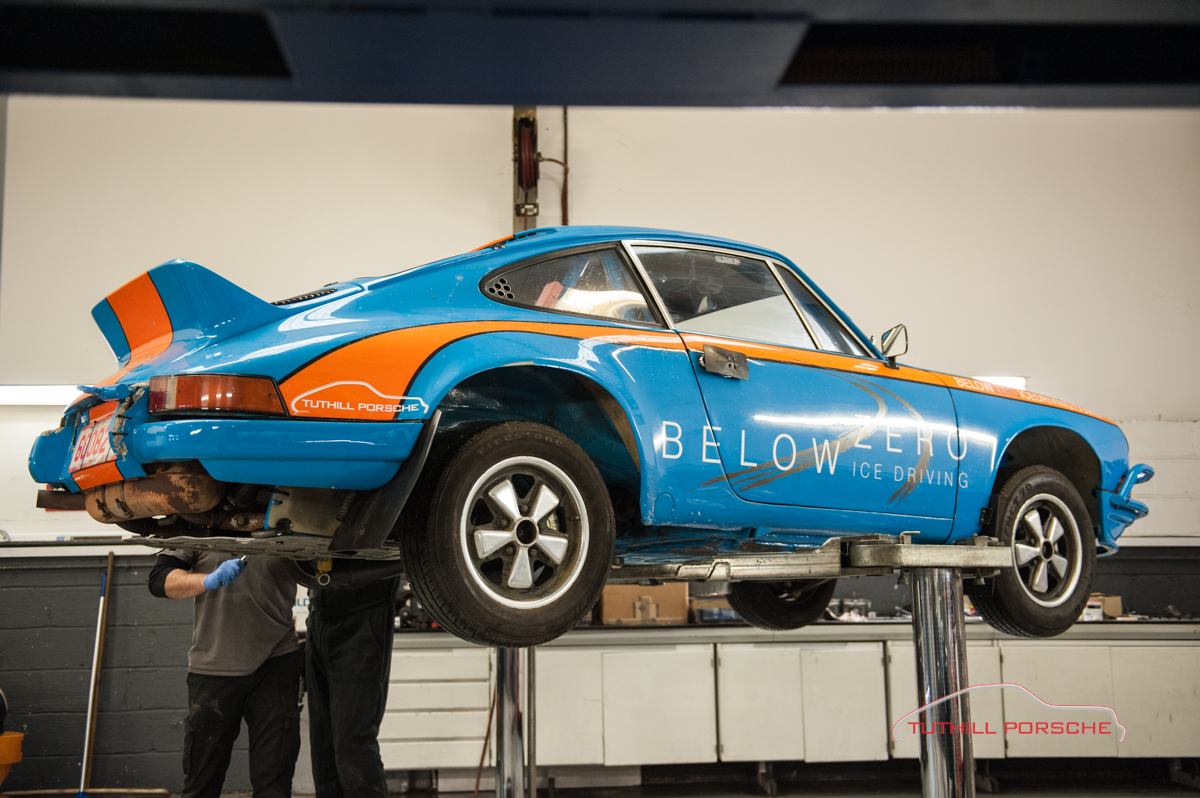

Once the fabrication team has carried out its work, the car goes to our bodyshop for a fresh coat of paint. The clean white backdrop of fresh Swedish snow really sets bright colours off perfectly, so we try to have an interesting and attractive array of cars and colours for our customers to choose from. This year we have some new colours, including Sky Blue on one of our early cars and Guards Red on a later 911.

When the shells come out of paint, they go to the rally workshop, where the mechanics begin the process of inspecting the mechanical parts and changing any brakes or dampers which require replacement. While the cars are run in a very safe environment, safety remains of paramount importance, so we check all seats and seat belts. All of these cars run our much improved wiring loom so electrics are usually totally reliable, but those systems also get checked regardless.

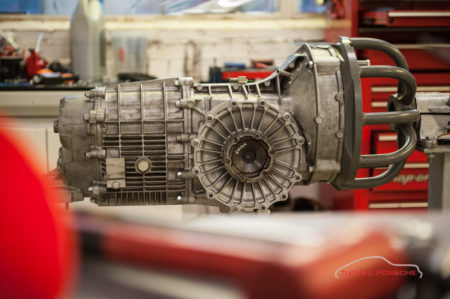

While the bodyshell has been in paint, the engine shop has stripped and checked the engine and transmission. Each engine comes apart to check condition and make sure it can operate reliably. When grip is low on snow and ice, so revs are high. This puts the engines under quite a bit of stress during a season, so a quick strip and rebuild gives us confidence.

The transmissions are also put under quite a bit of stress across a full Below Zero Ice Driving season, so each gearbox and differential is removed, stripped and checked for condition. Once the transmission has been rebuilt it goes back to its engine with a brand new clutch assembly and the engine and gearbox are put back in the car.

The final part of the process is a road test, to make sure everything works. Final sign off is normally carried out by Richard. Once a car has cleared that final hurdle, it is ready to go. Sweden is a long way away, so we move all of our cars using a huge enclosed car transporter, which usually picks them up during the first week of January and brings them home again in March. We are just about there with the cars for next year, so look forward to waving them off in a few weeks!

Are you interested in trying our Below Zero Ice Driving experience? Our bookings diary has been filling up fast for next year but we usually have car days available. Email tim@belowzeroicedriving.com to enquire.

Back to News

Back to News