We’ve reached the halfway point in our 2018 bespoke Porsche build reviews. Part six looks at our latest 911 Safari rally car.

12 Builds of Christmas 6: Porsche 911 Safari rally car

Tuthill Porsche is synonymous with rallying and our cars have travelled the globe in search of excitement. Building fast 911s is easily done, but making fast Porsches strong enough to withstand thousands of kilometres of rallying over the roughest terrain is a complicated undertaking involving all of our teams: fabrication, bodyshop, engine shop and the competition workshop. Hundreds of parts go into each build and the work would be impossible without our dedicated parts department.

This Porsche 911 rally car was built with the ultimate aim of competing in marathon rallies, such as the East African Safari Classic Rally. When we first discussed the build, the owner had never driven a rally before, but was drawn to the challenge and the idea that he and his partner could share an amazing adventure. The project therefore had two objectives: helping them to accumulate rallying experience and achieve the necessary qualifications, and building a car that could achieve their ambitions while keeping within a reasonable budget.

Work began in the competition workshop with the strip of the donor chassis. Many parts were retained for use in the rebuild, and the orders began to go out for the new parts that would be required. The bare chassis was sent for media blasting and returned to the fabrication shop to begin the long process of strengthening the shell for marathon events.

We supplied the base car for this build and it proved to be a really excellent shell with very little corrosion. While the owners would initially be taking on mainly local rallies, the duo were keen to enter marathon rallies also, so the car was built as a full Safari shell from the start.

The fabrication department fitted the bare shell to one of our Celette chassis jigs and began to add strength using our kit of Safari upgrades. Other techniques included seam welding, where seams of spot-welded panels are gas welded together at intervals to make the structure much stiffer. The fabrication work including full underbody guards, ‘roo bars’ and roll cage took almost eight weeks before the finished shell could be rolled into the bodyshop.

Painting the car was a normal process of cleaning, hand sanding, more cleaning, primer and paint. Our rally cars have full under-arch protection using liners so we tend not to employ too much heavy stonechip material unless the customer has a specific desire to do so.

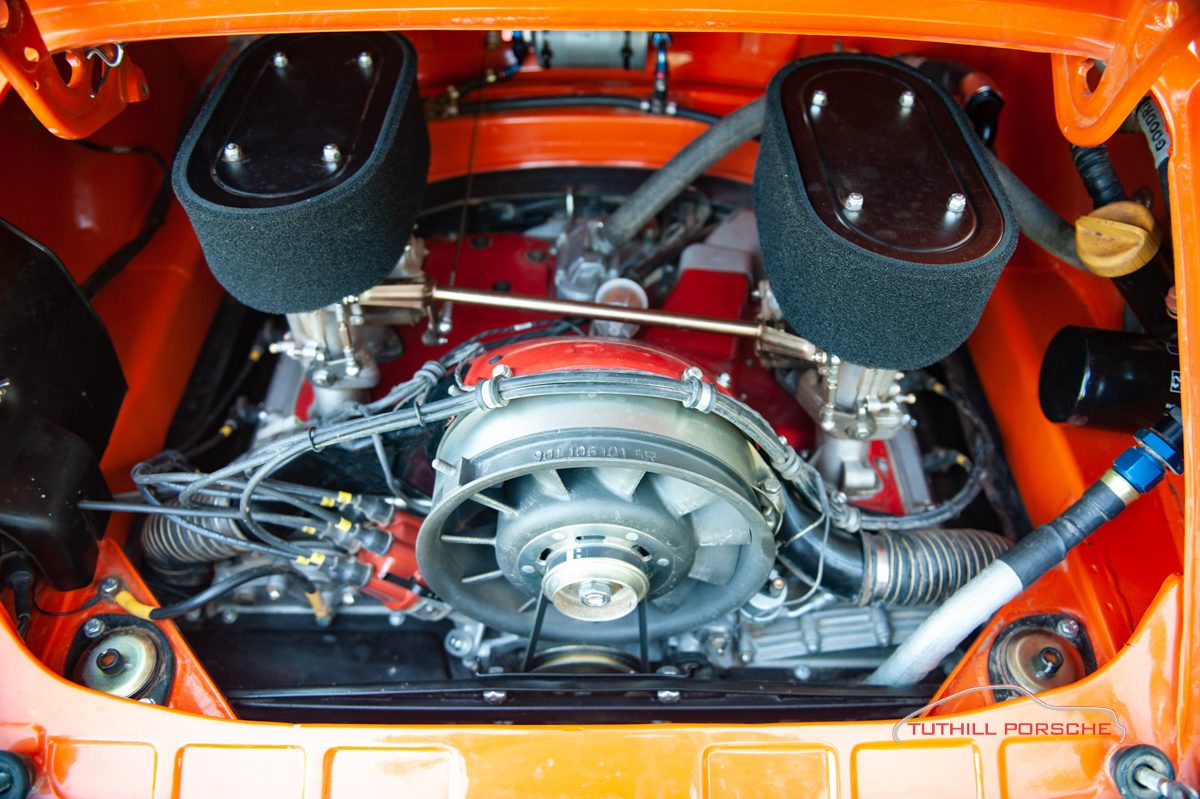

When the paint was done, the car came to the competition workshop, where a team of mechanics began the assembly including oil tank, coolers and lines, fuel tank, pumps and lines, a full competition wiring harness, fire extinguisher, rally suspension and brakes, competition seats and belts, rally time and distance meters and hundreds more parts. It also had a full-spec Safari engine and transmission package including limited slip differential.

The car enjoyed one UK rally before the new owners used it on their first marathon event: the 2018 Morocco Historic Rally. It also took part in the Woodpecker Rally in August and is heading to Sweden for a few days in January, where the owner will enjoy it on our Below Zero Ice Driving circuits. 2019 also sees the ninth edition of the East African Safari Classic Rally and this 911 is likely to be part of the excitement.

Back to News

Back to News